Introduction

Still, food product, medicinals, If you work in process engineering. These remarkably protean bias are among the most extensively used thermal operation results in the world — and for good reason. They offer high thermal effectiveness, a compact footmark, ease of conservation, and the inflexibility to gauge capacity up or down simply by adding or removing plates. But what exactly is a plate and frame heat exchanger, how does it work, and why has it come the favored choice for so numerous operations? This blog answers all of those questions and further.

The Basic Design and Construction

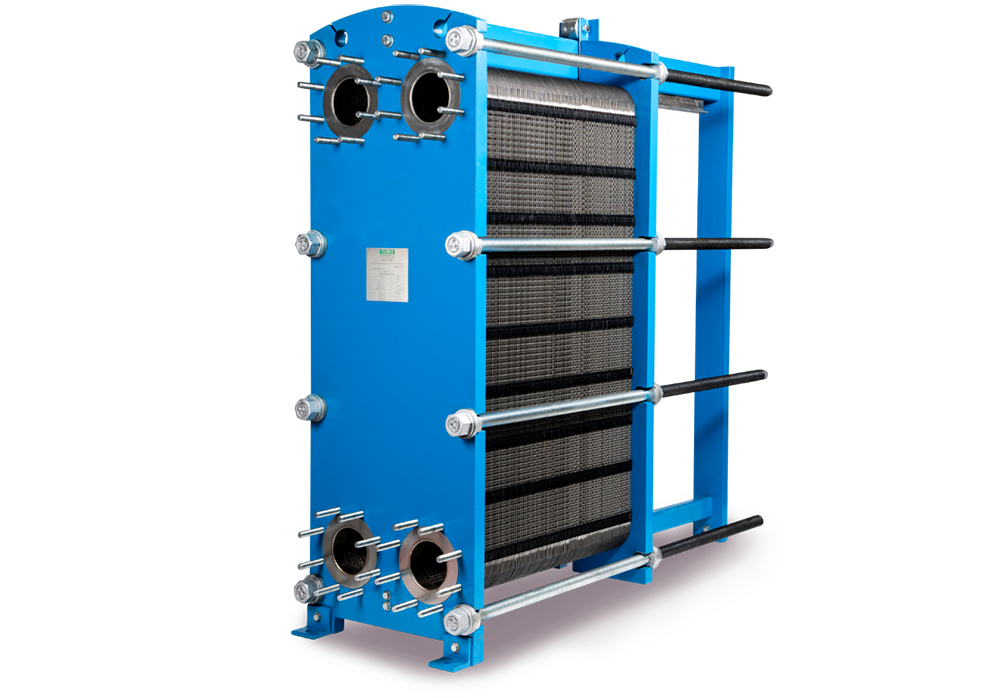

A plate and frame heat exchanger is a type of heat exchanger that transfers thermal energy between two fluid aqueducts using a series of thin, corrugated essence plates mounted within a rigid frame. The frame itself consists of a fixed frontal end plate, a portable hinder end plate, and a brace of carrying bars generally top and nethermost — along which the plate pack is arranged and clamped together using tensing bolts.

Each plate in the pack is pressed from a thin distance of essence — most generally pristine sword, though titanium, nickel blends, and other accoutrements are used depending on the operation — and features a corrugated or embossed face pattern. This corrugated figure serves two important purposes it provides structural severity to the plate under pressure, and it promotes turbulent inflow in the fluid channels, which dramatically enhances heat transfer performance.

Between each brace of plates sits a gasket, which seals the border of the channel and directs fluid inflow through the unit in the correct interspersing pattern. Hot fluid flows through one set of channels while cold fluid flows through the conterminous set, meaning every hot channel is adjoined on both sides by cold channels. This custom orco-current arrangement maximizes the temperature grade between the two aqueducts, performing in largely effective heat exchange.

How Does It Work?

The operating principle of a plate and frame heat exchanger is straightforward. Two fluid aqueducts — one that needs to be cooled and one that needs to be hotted — enter the unit through separate bay anchorages on the end plate. They're also directed by the gaskets into interspersing channels within the plate pack, flowing in contrary directions to each other( custom inflow) for maximum thermal effectiveness.

As the fluids travel through their separate channels, heat passes through the thin essence plate walls from the hotter fluid to the cooler one. Because the corrugated face creates turbulence and the plates are veritably thin, the rate of heat transfer is exceptionally high. The heated or cooled fluids also exit through their separate outlet anchorages and return to the process.

One of the most significant advantages of this design is the extremely high face- area- to- volume rate it achieves. Compared to a traditional shell- and- tube heat exchanger of original thermal duty, a plate and frame unit is frequently a bit of the size and weight — a critical advantage where bottom space is limited.

Key Advantages of Plate and Frame Heat Exchangers

The fashionability of this technology across so numerous diligence is no accident. Several characteristics set it piecemeal from contending designs.

Thermal Efficiency: TheThe turbulent inflow generated by the corrugated plates, combined with the custom inflow arrangement and the large effective face area, allows plate and frame units to achieve veritably close temperature approaches occasionally as tight as 1 °C between the two aqueducts. This position of effectiveness is delicate to match with other heat exchanger configurations.

Scalability and Flexibility: Because the thermal capacity of the unit is determined by the number of plates in the pack, capacity can be acclimated simply by adding or removing plates. This makes the design ideal for processes where heat duty conditions may change over time.

Easy Maintenance and Cleaning: The bolted frame construction means the entire plate pack can be disassembled snappily and each plate gutted or audited collectively. This is a major advantage in diligence similar as food and libation, dairy, and medicinals, where hygiene norms demand regular and thorough cleaning.

Compact Footprint: For a given thermal duty, plate and frame units bear significantly lower bottom space than shell- and- tube designs, making them well suited for installations where space is at a decoration.

Cost-Effective Operation: Lower fouling tendencies, high effectiveness, and straightforward conservation restate into reduced operating costs over the life of the outfit.

Common operations Across diligence

Plate and frame heat exchangers are used across an impressively broad range of sectors. In the food and libation assiduity, they pasteurize milk, juice, and beer with perfection and aseptic trustability. In HVAC and quarter energy systems, they serve as insulation heat exchangers between primary and secondary circuits. In chemical processing, they handle aggressive fluids using titanium or high- amalgamation plates. In pharmaceutical manufacturing, they give the precise temperature control that sensitive natural and chemical processes demand. In power generation, they're used in cooling water systems and waste heat recovery operations.

Why Kinetic Engineering Is Your Trusted Heat Exchanger Partner

opting the right heat exchanger for your specific process is a decision that has long- term consequences for effectiveness, trustworthiness, and operating cost. Kinetic Engineering brings decades of moxie in perfect thermal operation, offering a comprehensive portfolio of heat exchangers designed and erected to perform in the most demanding artificial surroundings. Their engineering platoon works nearly with guests from original specification through to installation and commissioning, icing that every result is optimized for the process at hand. Whether you need a standard unit or a completely custom- finagled design, Kinetic Engineering has the knowledge, manufacturing capability, and commitment to quality to deliver.

Conclusion

A plate and frame heat exchanger is far further than a simple piece of process outfit — it's a perfection- finagled thermal operation tool that delivers outstanding effectiveness, inflexibility, and trustability across a vast range of diligence and operations. Its elegant design, combining corrugated plates, a robust setting frame, and perfection gaskets, enables it to transfer heat with a position of effectiveness that many other technologies can match at similar cost and size. Whether you're designing a new installation, upgrading an being system, or simply trying to understand the technology that underpins your process, the plate and frame heat exchanger is well worth getting to know. With the right outfit and the right engineering mate behind you, it can be one of the most precious means in your operation.